REF 110.03

Permanent magnet - neodyme type AN 03

-

- Neodynium magnet

-

- High holding power

-

- Neodynium magnet

-

- High holding power

Neodymium-iron-boron magnets are sintered magnets made of Neodymium, iron and boron powder. A surface treatment is essential to protect surface treatment is necessary to protect against corrosion (Zinc-Nickel-Gold-Epoxy).

Neodymium Iron Boron have a very high magnetic energy and a very high resistance to demagnetisation. They are brittle ceramics.

The carrying capacity is optimal when the magnet is in contact with a clean, soft steel, clean and sufficiently thick. It decreases for alloyed steels (cast iron -30%), because of an air gap or because of a temperature rise (-0.11% per degree C).

Neodymium Iron Boron have a very high magnetic energy and a very high resistance to demagnetisation. They are brittle ceramics.

The carrying capacity is optimal when the magnet is in contact with a clean, soft steel, clean and sufficiently thick. It decreases for alloyed steels (cast iron -30%), because of an air gap or because of a temperature rise (-0.11% per degree C).

- Neodymium magnets cannot be machined, they cannot be cut or drilled.

- The assembly is done by gluing.

-

Use :

- Relay

- Sensor

- Lock

- Separation

- Clamping

-

Max. temperature of use :

- 80 (180°) °C

-

Density :

- 7.5 gr/cm³

-

Max. surface induction :

- 5000 (N35) G

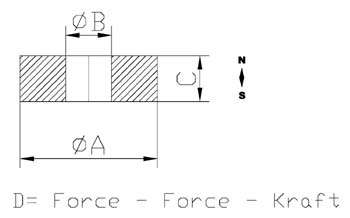

| Qty | Product | Weight in kg | A | B | C | D |

|---|---|---|---|---|---|---|

| 110.03-6x2x2 | 0.0004 | 6 | 2 | 2 | 6.4N | |

| 110.03-10x4x5 | 0.0025 | 10 | 4 | 5 | 20N | |

| 110.03-10x5x5 | 0.0026 | 10 | 5 | 5 | 25N | |

| 110.03-10x7x3 | 0.0009 | 10 | 7 | 3 | 4N | |

| 110.03-12x3.5x3 | 0.0022 | 12 | 3.5 | 3 | 18N | |

| 110.03-15x4.5x3.5 | 0.0037 | 150 | 4.5 | 3.5 | 29N | |

| 110.03-15x5x5 | 0.006 | 15 | 5 | 5 | 35N | |

| 110.03-15x6x6 | 0.007 | 15 | 6 | 6 | 48N | |

| 110.03-15x7x2 | 0.003 | 15 | 7 | 2 | 35N | |

| 110.03-18x4.5x4 | 0.007 | 18 | 4.5 | 4 | 41N | |

| 110.03-19x9.5x6.4 | 0.010 | 19 | 9.5 | 6.4 | 77N | |

| 110.03-20x10x6 | 0.011 | 20 | 10 | 6 | 75N | |

| 110.03-24x5.5x4 | 0.014 | 24 | 5.5 | 4 | 66N | |

| 110.03-25x6x6 | 0.020 | 25 | 6 | 6 | 70N | |

| 110.03-26x23x5 | 0.005 | 26 | 23 | 5 | 40N | |

| 110.03-26.75x16x5 | 0.014 | 26.75 | 16 | 5 | 85N | |

| 110.03-27x15x6 | 0.018 | 27 | 15 | 6 | 90N | |

| 110.03-27x15x10 | 0.030 | 27 | 15 | 10 | 110N | |

| 110.03-32x10.5x2 | 0.011 | 32 | 10.5 | 2 | 42N | |

| 110.03-38x12x4 | 0.030 | 38 | 12 | 4 | 110N | |

| 110.03-48x15x5 | 0.060 | 48 | 15 | 5 | 165N | |

| 110.03-56x15x6 | 0.102 | 56 | 15 | 6 | 230N | |

| 110.03-60x30x6 | 0.095 | 60 | 30 | 6 | / | |

| 110.03-60x30x10 | 0.160 | 60 | 30 | 10 | / | |

| 110.03-60x6x30 | 0.620 | 60 | 6 | 30 | 1200N |

indication_tableau_dessus

indication_tableau_dessous