Permanent magnets for automation

Magnets are an important tool in automation for handling workpieces and materials.

They offer a number of advantages over conventional methods such as hoists or grippers, including

Accuracy: magnets can position and hold workpieces very precisely.

Safety: Magnets are a safe and reliable method of handling workpieces.

Efficiency: Magnets can increase productivity by automating handling tasks.

Magnets are used in automation in a variety of applications, including

Safety: Magnets are a safe and reliable method of handling workpieces.

Efficiency: Magnets can increase productivity by automating handling tasks.

Magnets are used in automation in a variety of applications, including

Assembly: Magnets can be used to assemble workpieces by pulling or holding parts together.

Handling: Magnets can be used to handle workpieces by lifting, moving or positioning them.

Sorting: Magnets can be used to sort workpieces by material or shape.

Handling: Magnets can be used to handle workpieces by lifting, moving or positioning them.

Sorting: Magnets can be used to sort workpieces by material or shape.

Waste disposal: Magnets can be used to remove metal waste from other materials.

In robotics, magnets are often used to handle workpieces. Magnetic grippers can be used with robotic arms to lift, move and position workpieces with high precision and safety.

In robotics, magnets are often used to handle workpieces. Magnetic grippers can be used with robotic arms to lift, move and position workpieces with high precision and safety.

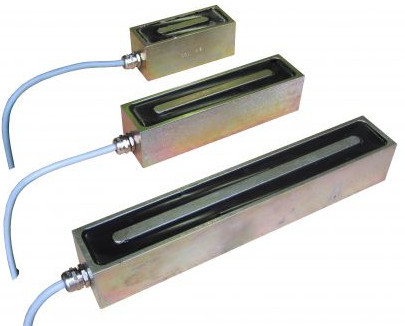

There are two main types of magnetic grippers: 1) Permanent magnetic grippers: These grippers use permanent magnets to attract workpieces. They are easy to use and do not require a power supply.

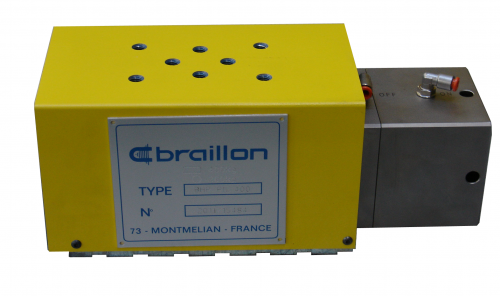

2) Electropermanent grippers: These grippers use electromagnets to attract workpieces. They can generate stronger forces than permanent magnetic grippers, but are also more complex and require a power supply.

Choosing the right magnetic gripper depends on a number of factors, including

1) Type of workpiece: the gripper must be strong enough to lift and hold the workpiece.

2) Shape of the workpiece: The gripper must be able to accommodate the shape of the workpiece.

3) Environment: The gripper must function safely and reliably in the environment # For more information about our magnets for Rotober in automation, please contact us. We will be happy to advise you on selecting the right magnets for your application.

10 results

Sort :